Hey, gang!

As promised this is the second instalment of my experience in Rwanda. In this post, we take a closer look at the processing of coffee cherries at the stations and how we select the lots.

Cupping

Cupping is how we taste coffees to determine the overall quality. Once we taste it, the coffee is graded out of 100, with everything above 80 points being considered “specialty”. In the short space of time we were in Rwanda we tasted close to four hundred different lots, which accounted for the year's harvest. Each one of those lots gets roasted, tasted and graded, so we had a busy first week for sure!

Cupping at origin, I quickly saw how different it was to production cupping back at the roastery. Because there were so many samples to get through in a single day, the pace was a lot faster than what I am used to. Every lot needed to be scored fairly as well, making efficiency key.

Another key difference was the coffees we tasted were all Rwandan. After the first few tables, the subtle differences between stations became clearer. By the end of the week, we were even throwing out guesses for what stations the different samples were coming from. It was definitely a unique opportunity being able to taste so many coffees in such a short space of time. An opportunity that is hard to experience outside of origin.

After cupping, we traveled across the stunning Rwandan countryside with Muraho Trading Company. At the stations, we were introduced to the workers and walked through the different processes.

Coffee Growing in Rwanda

Typically in Africa, one station will buy coffee cherries from many small-holder farmers. The farmers grow other cash crops as well to subsidise their incomes throughout the year. Farmers deliver their cherry to a central washing station and get paid based on weight. Hundreds of individual farmers often contribute to a single station’s yearly production.

When we were at Shyira washing station we were introduced to some local farmers. We "helped out" picking cherries and needless to say the farmers schooled us all on how to pick. Next up we headed down to the stations to see how processing happens.

Processing

Selective picking and best growing practices are essential for a quality end product. Another key to quality is how the stations process the cherries. Gaudam and Emmanuel from Muraho walked us through the various steps of coffee processing. I definitely had a lot of light bulb moments seeing firsthand how everything comes together.

After the farmers bring in the cherries they lay them on tables and pick out any obvious defects. The cherries are then floated in tanks of water, where the “floaters” are removed. Floaters are the cherries that are the lowest density and usually the lowest quality.

The cherries then pass through a de-pulper, which removes the skin and most of the flesh from the beans. This process leaves sticky mucilage covered beans, which then go to fermentation tanks.

This is where the hard work starts. When the sugars start to ferment the mucilage get’s broken down enough that it can be washed off. To help speed up the fermentation process a team of really fit guys get into the tank to stomp the beans. This process is to help speed up fermentation and help the sugars break down. They stomp the coffee for around 20 minutes or five rounds of the song “Hobe, Hobe, Hobe”. “Hobe” roughly translates to a warm embrace or welcome, which is a word you hear a lot at the stations. After the end of a couple of rounds of “Hobe”, I was shattered!

The coffee goes through the grading and washing channels after fermenting. Workers wash off the sticky mucilage from the coffee. The channels also separate the coffee into different density grades. Different gates of increasing height separate the channels. As the coffee travels down the channels the lower densities float over the top of the gates. This system is very effective at separating the different densities and plays a big role in the final score the lots receive.

Once the coffee is washed and separated it is laid on raised beds to dry, which can take around a month. The coffee is constantly turned throughout. It is also hand sorted for any defects that snuck through the previous stages of quality control. The coffee then gets bagged up and taken to a central dry mill in Kigali. It get's milled to remove the parchment that surrounds the bean. Finally, the coffee is ready for grading and export.

Honey and Naturals

The first legally produced honey and natural processed coffees from Rwanda came from Muraho last year. The change in legislation is a massive and very exciting step forward for the Rwandan coffee industry and Muraho has been smashing it with the quality of both.

Natural processed coffees skip the pulping, fermenting and washing stages and go straight on to the tables. The sun dries the cherry around the bean like a raisin and the cherry ferments around the beans inside. This procedure takes on average 40 – 45 days. After being fully dried they get milled. Typically naturals have lots of funky fruity flavours and high sweetness.

A honey is a somewhere in between a washed and natural. The cherry is pulped and put out to dry with the mucilage left on, skipping the washing and separating stage. The drying process takes on average 35 days. This process also produces some unique and complex flavours.

One of the things that struck me the most when visiting the stations was how extensive all the different levels of quality control are. A lot of work goes in to producing these coffees and it translates to the final product.

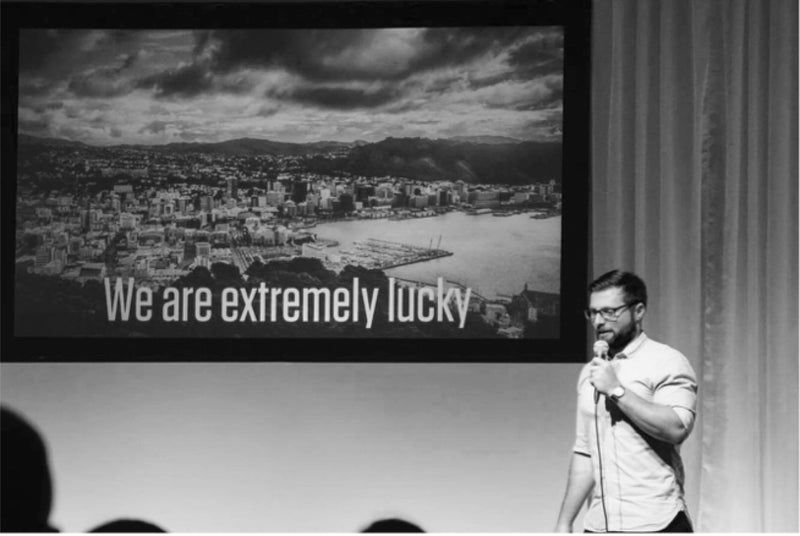

This trip was truly eye opening for me. There is some very exciting stuff coming out of these stations. Full credit goes to Muraho and the teams at the stations who work hard to produce some incredible coffees. Make sure you watch this space as the fresh harvest is almost here and we’ll be releasing the new coffees soon!

If you’ve made it this far, thanks for reading and we’ll keep you updated with more origin trips in the future. Both to Rwanda and other coffee producing countries.

Nic Rapp