Coffee’s journey from farm to cup is complex, varied and crucial to quality. We’ve released an infographic to help show how this journey works and how we do things differently. If you want a little more detail, then read on.

Growing

Coffea Arabica is a scrupulous plant. It will only grow where the conditions are right. The conditions are only right in a select few places, between the Tropics of Cancer and Capricorn, in an area around the equator known as ‘The Bean Belt’. No, really. That’s what it’s called.

Having evolved in the Ethiopian Highlands, coffee has adapted to thrive in specific conditions. It generally grows best at altitudes of between 800 – 2000 metres above sea level.

The coffee plant prefers warm temperatures with periods of high rainfall. Central and South America, North East Africa, and South East Asia Pacific all provide these conditions. These regions also offer the volcanic soil that the coffee plant prefers.

Coffee plants take 3-5 years to reach maturity. At the end of the rainy season, small white flowers will begin to appear. These will eventually give way to little green buds, which slowly grow into cherries. The seeds of these cherries are your coffee beans.

Harvesting

Specialty grade coffee is hand-picked. This might seem labour intensive, but it's one of the best ways to ensure quality. The ripest fruit produces the best tasting cup of coffee. The coffee cherries ripen at different speeds, so the same tree may have fruit that is flowering, green, ripe and overripe, all maturing at the same time. Hand picking means the cherries are picked at the optimum stage, and less undesirable coffee goes on to processing. It also leads to larger potential yields.

Many coffee producers will then have the cherries sorted again, to remove any unwelcome fruit that may have slipped through.

Less quality focused farms may employ strip-picking (hand stripping the branches) or machine picking strategies. These can result in lower quality coffee as more defective cherries can be harvested.

Processing

Processing is essentially what happens to the coffee cherries after picking to separate the green beans from the rest of the fruit. This is a crucial stage of production, and has a huge influence over the final cup quality. During processing, coffee is fermented, either with or without water. This, coupled with other factors like the duration and temperature of the fermentation, has a pronounced effect on the flavours in the cup.

Washed/wet process

Washed coffees are pulped and left to soak in tanks of water. The water breaks down and the fruit flesh as it ferments. The fermented beans (still covered in a protective layer known as parchment) are laid out to dry. Typically this will give a clean cup profile, with distinct, refined flavours.

Natural/dry process.

During this method the cherries are cleaned and laid out to dry in their picked form. Fermentation occurs during the drying process. You might expect a complex cup, with pronounced tropical fruits and berries, heavy body and lots of sweetness.

Honey/semi-dry/semi-washed

Less common than the other two methods, but no less delicious. Honey processed coffees are pulped before drying, removing the skin and exposing the fruit flesh, which becomes golden and sticky (like honey) as it ferments and dries. The cup profile of Honeys can sit anywhere between a washed and a natural, depending on how much flesh is left on for how long.

Drying

Drying normally takes place outside with parchment coffee or cherries lying out in the sun. They will be spread out on patios or on raised netted tables (for extra airflow). Over a period of up to four weeks, the beans will be raked or turned to ensure even drying. Once they reach their target moisture content of 10-12% the parchment coffee will be stored until ready for export. In some cases, the drying may be done mechanically. This can have an impact on quality and is usually only done if the weather doesn’t allow for sun drying.

Before the coffee is exported the parchment is removed by milling, leaving just the green bean. The resulting beans will be sorted to remove undersized or defective beans, as well as any foreign matter. This process will often be performed by hand. This is an important stage, as these defects directly affect the quality and taste of the coffee, often resulting in a lower price being paid to the farmer.

Grading

Samples of the coffee will be roasted and ‘cupped’ by green coffee buyers like our old mates at Raw Material. The coffee is roasted in small batches of 100g on a sample roaster 12 to 24 hours before they are cupped. Cupping is a standardised method of tasting and evaluating a coffee’s qualities. The coffee is brewed to exact specifications so as to be a consistent system of testing.

The coffee is then tasted and scored on a scale of 1-10 on categories like Fragrance/Aroma, Flavour, Aftertaste, Acidity, Body, Sweetness, Uniformity, and whether or not there are any defects present. There are a total of 100 points available. A score of 80 points or higher means that the coffee is considered ‘Specialty Grade’. This score is linked to the potential price for the coffee.

Pricing

So, this is where we do things differently. Traditional models of coffee trading have not always been great for coffee farmers. One of the key issues that farmers face is the Coffee Futures Market. The price of most coffee is dictated by some Wolf of Wall Street types snorting cocaine off each others’ Ferraris. Okay, so that’s not strictly true, but the price does change according to what the market dictates – but the market assumes that all coffee is of the same (pretty low) quality.

Essentially, this means that the price that a producer can expect to be paid fluctuates wildly. We’re all pretty much agreed that isn’t fair on farmers, since often this means the ‘value’ of their coffee is less than it cost them to produce. Some organisations, such as Fair Trade seek to redress this by paying a premium on top of the market price. This is pretty good, as it means the producer stands to make a little more (or lose a little less) money. The downside is that the actual amount they will receive is still an unknown. The price still fluctuates with the market.

Our fixed price model means that no matter what the market is doing, the crop is worth the same. We work closely with farmers to ensure that their crop sits in the Specialty market and even pay bonuses if the quality is particularly high. This model means farmers are better able to plan for improvements to their farm systems, which may increase quality or yield.

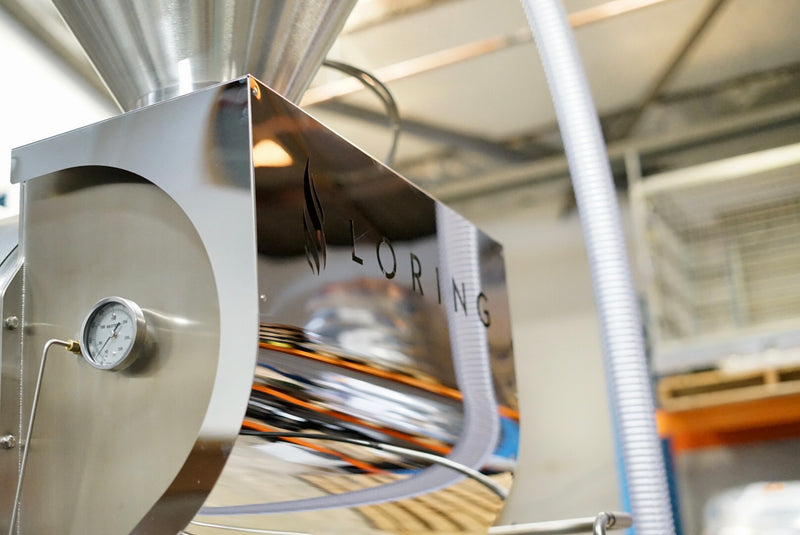

Roasting

Once that sweet green coffee finally makes it to our HQ, we roast it up a treat in either Betty, our Probat UG-22, or Dee-Dee, our Diedrich IR3. We then go through more cupping to ensure that the quality of the coffee is still high. We’ll also try a few different roasts to ‘dial in’ our preferred roast profile for that coffee.

Roasting exposes green coffee to heat to encourage a series of chemical reactions within the bean. The process allows much of the material in the coffee to become more soluble, making it possible for the coffee to dissolve in water.

Roasting is responsible for the development of much of the flavour in coffee. An ideal roast allows the natural flavours of the coffee to come through, without any ‘roasty’ tastes developing. It’s also important to allow enough development of the roast to ensure there are no green, grassy flavours left hanging around.

You can think of it like cooking a steak. You can’t cook great flavour into a low quality piece of meat. But it’s just as true that no matter how good the meat, if you undercook or overcook it, then it’s not going to live up to its potential. But you if you take great ingredients and cook them to perfection, the results can be spectacular.

Quality Control

The following morning, before any coffee is sent out, we’ll cup samples from each roast to make sure that we’re happy with how every coffee tastes. Once we’re all in agreement, our dispatch team get all the coffee bagged up, boxed up, and shipped out, making sure it arrives fresh to your front door or your favourite café.

Brewing

Now it’s over to your local barista to make sure that hard work is worthwhile. Specialty baristas will follow strict recipes to bring out the best from the beans again and again. They’ll be controlling grind size, brew time, and coffee-to-water ratio. Alternatively, if you’re brewing at home, that responsibility lies with you. If that sounds a little daunting, don’t worry we’ve got you covered there’ll be some posts to come with the tricks of the trade that we use to get great tasting coffee every time.

Shop expand_more

-

Coffee

-

Cans

-

Subscriptions

-

Equipment & Accessories

-

Gifts & Merch

-

Pantry

-

Brands

local_shipping

Free urban shipping

On orders $35 & over

local_shipping

Free rural shipping

On orders $50 & over

coffee

Subscribe & save

Fresh coffee delivered